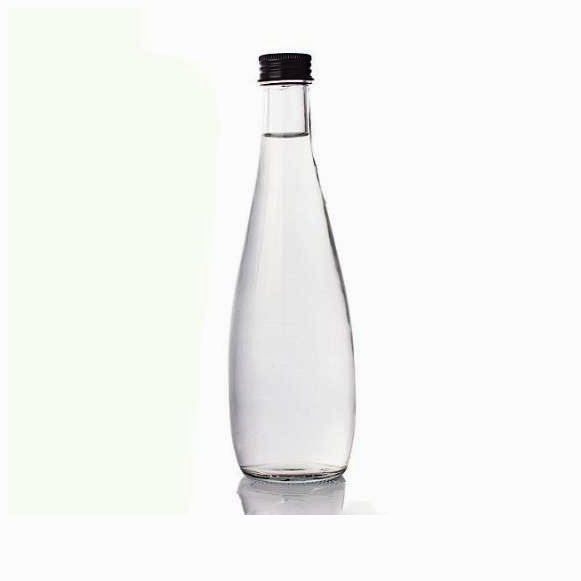

330ml Clear Juice Bottle with Screw Cap

Why choose glass bottled water /juice /beverage ?

1. The glass material has good barrier properties, which can prevent oxygen and other gases well, and at the same time prevent the volatile components of the contents from volatilizing into the atmosphere.

2. The glass bottle can be used repeatedly, which can reduce the packaging cost.

3. Glass can easily change color and transparency.

4. The glass bottle is hygienic, has good corrosion resistance and acid corrosion resistance, and is suitable for the packaging of acidic substances (such as vegetable juice drinks, etc.).

our products

This water bottle is suitable for: juice, beverage, soda, mineral water, coffee, tea, etc.,and our water glass bottle can be recycled.

We support customization of capacity, size, bottle color, and Logo, and provide one-stop services, such as matching aluminum caps, labels, packaging, etc.

Any questions, please feel free to contact us.

Features

⚡ In our production workshop,the production process of glass beverage bottles mainly includes the steps of raw material preprocessing, batch preparation, melting, forming and heat treatment. Raw material preprocessing is to pulverize bulk raw materials (quartz sand, soda ash, limestone, feldspar, etc.), dry wet raw materials, and remove iron from iron-containing raw materials to ensure the quality of glass.

⚡ Batch preparation and melting means that the glass batch is heated at a high temperature of 1550-1600 degrees in a pool kiln or pool furnace to form a uniform, bubble-free liquid glass that meets the molding requirements. Forming is to put the liquid glass into a mold to make glass products of the required shape.

Glass bottles can be used in juice, beverage, milk, water, alcoholic beverages, coffee, etc.

⚡ Let’s take carbonated beverages as an example: glass materials have strong barrier properties, which can not only prevent the influence of external oxygen and other gases on beverages, but also minimize the volatilization of gases in carbonated beverages to ensure that Carbonated beverages maintain their original flavor and texture. In addition, the properties of glass materials are relatively stable, and generally do not react during the storage of carbonated beverages and other liquids, which not only does not affect the taste of beverages, but also glass bottles can be recycled and reused, which is conducive to reducing the packaging cost of beverage manufacturers.

⚡ We provide one-stop service, including metal caps, label and packaging, support to customize other shapes, capacities and different logos, any questions Feel free to contact us any time.

Details

The Process Flow

Paint Spraying

Molding

|

capacity |

330ml |

|

product code |

V2122 |

|

size |

68*68*240mm |

|

net weight |

420g |

|

MOQ |

40HQ |

|

Sample |

Free supply |

|

Color |

Clear and Frosted |

|

surface handling |

screen printing painting |

|

sealing type |

Screw cap |

|

material |

soda lime glass |

|

customize |

logo printing/ Glue Label/ Package Box/ New Mold New Design |